The smart Trick of Premier Aluminum Llc That Nobody is Talking About

The smart Trick of Premier Aluminum Llc That Nobody is Talking About

Blog Article

The 8-Second Trick For Premier Aluminum Llc

Table of ContentsGetting The Premier Aluminum Llc To WorkSome Known Questions About Premier Aluminum Llc.The 4-Minute Rule for Premier Aluminum LlcHow Premier Aluminum Llc can Save You Time, Stress, and Money.

(https://sandbox.zenodo.org/records/142041)Generally, a purchaser's main obligation was to locate qualified and responsive suppliers. In many cases, purchasers assumed that any type of provider happy to contractually satisfy the purchase need was qualified. Using reduced price and unqualified providers can create top quality issues, and squandered time and cash in the long run. To help you through the procedure, right here are some things to think about when selecting the appropriate metal casting vendor.

For instance, a company that only utilizes the investment spreading procedure will certainly try to sell you on why that procedure is best for your application. What if using the sand spreading procedure is best for you and your demands? Rather, look for a vendor that provides an array of casting processes so the very best choice for YOU is selected

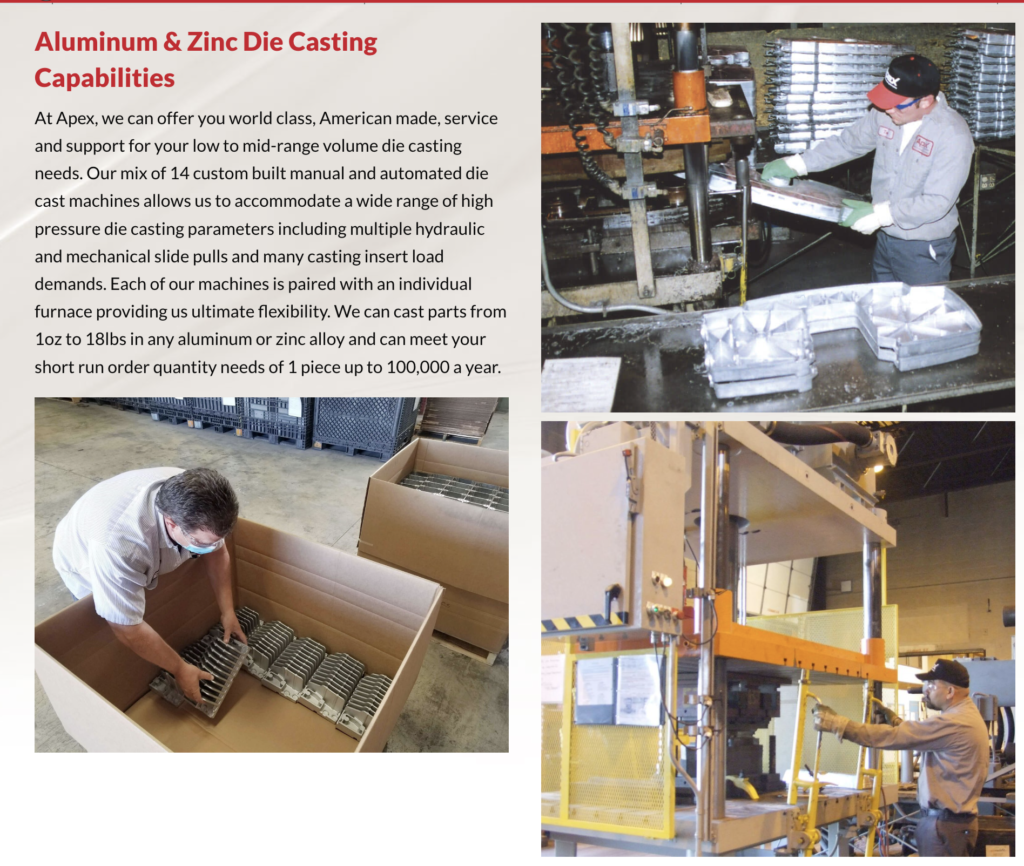

If working with a solitary resource for every one of your casting needs is necessary to you, the vendor needs to be varied in its abilities. When combined with various other integrated capacities, this can assist streamline and press the supply base. When picking the appropriate spreading supplier, mindful consideration needs to be offered to top quality, service, and rate.

All about Premier Aluminum Llc

Buyers increasingly select casting distributors that have machining capacities. If the spreading provider finds a problem during machining, the trouble is resolved faster with no disagreement over whose fault it is.

Trouble or no, integrated machining simplifies the supply chain and minimizes handling time and shipping price prior to the product makes it to the customer. What do you need from your casting supplier? Are you trying to find a person to just provide a metal component to your front door or do you require a lot more? If you do not have in-house metallurgy proficiency, validate that the vendor can provide advice in picking the proper alloy based on your details application.

Others will certainly exceed the letter of the PO to help you save time and cash. Do you have demands for both ferrous and non-ferrous alloys? Some factories are limited or specialized. Ensure the vendor can satisfy all your material or alloy requirements to remove the requirement for several distributors.

10 Easy Facts About Premier Aluminum Llc Explained

Research the vendor's internet site. Talk with a sales rep or service associate. Ask a great deal of questions. Visit their facility. Get an understanding of what they can do for you and if you can see on your own constructing a strong, shared connection with them.

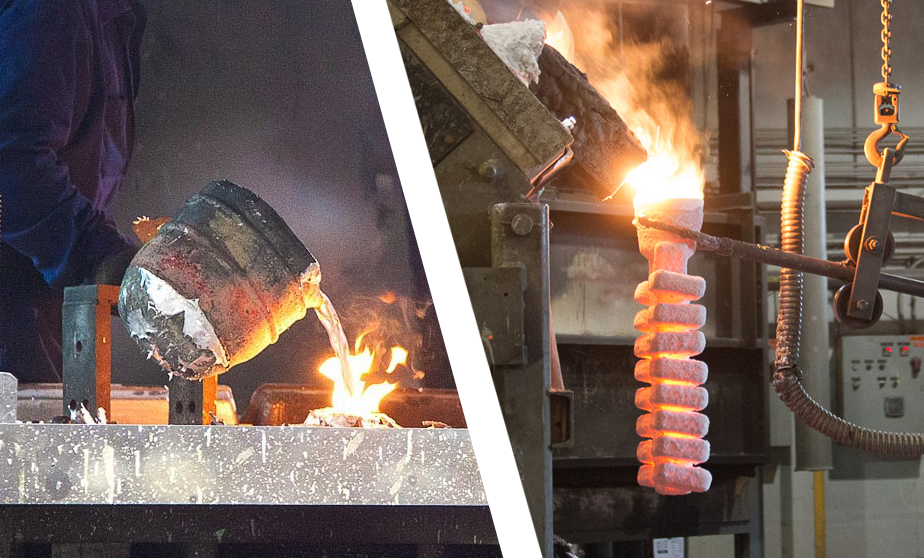

Light weight aluminum is additionally light-weight and has great corrosion resistance, making it suitable for applications where weight and toughness are crucial factors. Additionally, light weight aluminum casting is a cost-efficient method of manufacturing, as it needs less power and sources than other methods. Iron spreading, on the other hand, includes putting liquified iron right into a mold to produce a desired shape.

The 7-Minute Rule for Premier Aluminum Llc

Iron spreading is additionally able to endure high temperatures, making it suitable for use in applications such as engine components and commercial equipment. Nonetheless, iron casting can be more pricey than light weight aluminum spreading as a result of the higher price of resources and the energy required to melt the iron. When choosing in between light weight aluminum spreading and iron spreading, it is necessary to think about the certain demands of the application.

In conclusion, both aluminum spreading and iron spreading have their very own one-of-a-kind advantages and downsides. There are three sub-processes that fall under the group of die casting: gravity die casting (or permanent mold and mildew spreading), low-pressure die spreading and high-pressure die spreading. To get to the ended up item, there are three primary alloys used as die casting material to choose from: zinc, light weight aluminum and magnesium. Report this page